Lentiviral Vector

Lentiviral vector upstream and downstream process development and optimization for manufacturing

Improving the Current Industry Standard

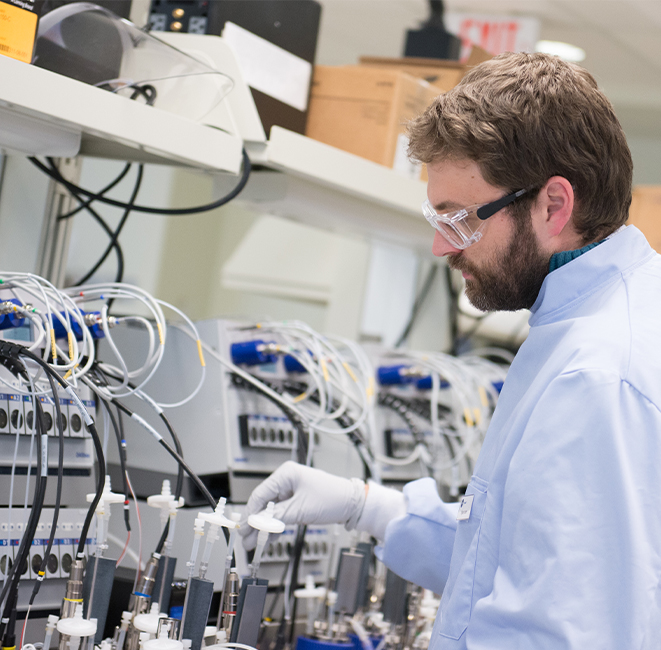

OmniaBio’s experienced process development team is adept at scaling-up lentiviral vector (LVV) production by establishing customized processes that are efficient and reliable. Our goal is to create a reproducible, closed, scalable process, improving upon the current industry standard to generate best-in-class recovery rates in downstream purification.

Lentiviral Vector Offerings

- LVV production in serum-free suspension culture

- LVV production using producer or packaging cell lines and transient transfection

- Closed system processing at each unit operation, including in-process testing

- Harvest and clarification steps enabled by scalable filtration technology

- A tailored approach to purification through access to a variety of chromatography resins

- Optimization of sterile filtration for up to 70 per cent recovery at the 1 L scale

Services for Your Project Phase

Process

Development

Experts in optimization to ensure reliable scale-up to produce cell and gene therapies.

GMP

Manufacturing

Our state-of-the-art facility is equipped with the tools and flexibility to manufacture your product at a commercial scale.

Analytical

Development

Providing a robust suite of analytical capabilities that are integrated through your product’s lifecycle to support the development process.

Regulatory

Support

With in-depth knowledge, we can guide you through the regulatory landscape to approval.