Cell Therapy Process Development

Achieving seamless, scalable cell therapy production requires processes as unique as your product. At OmniaBio, we champion a collaboration-first approach backed by next-generation technologies and proven process development expertise to deliver best-in-class manufacturing solutions tailored to your cell therapy program.

Redefining CAR-T Cell Therapy Manufacturing

With our Hamilton Intelligent Factory, we redefine manufacturing through the integration of artificial intelligence (AI) and robotics, delivering transformative efficiencies across critical areas to shorten GMP manufacturing and vein-to-vein timelines, lower cost of goods (COGs), and enhance the accessibility of CAR-T cell therapies.

12 Years

of Process and Analytical Development Expertise

+70

Dedicated Process and Analytical Development Scientists

19,500 ft2

Process Development Space

Seamless Scale Up From Process Development to Manufacturing

With over a decade of experience, our integrated team of cell therapy process development experts and MSAT scientists collaborate closely to establish, optimize, and scale up your production processes so you can expedite your product from development to manufacturing.

Our capabilities include:

- Immunotherapy – Best-in-class solutions for cell therapy development and manufacturing

- iPSC – Industry-leading experience and capabilities in stem cell-based therapies

- Lentiviral Vectors – Enhancing gene delivery through end-to-end development support

Tech Agnostic Capabilities: Innovation At Your Service

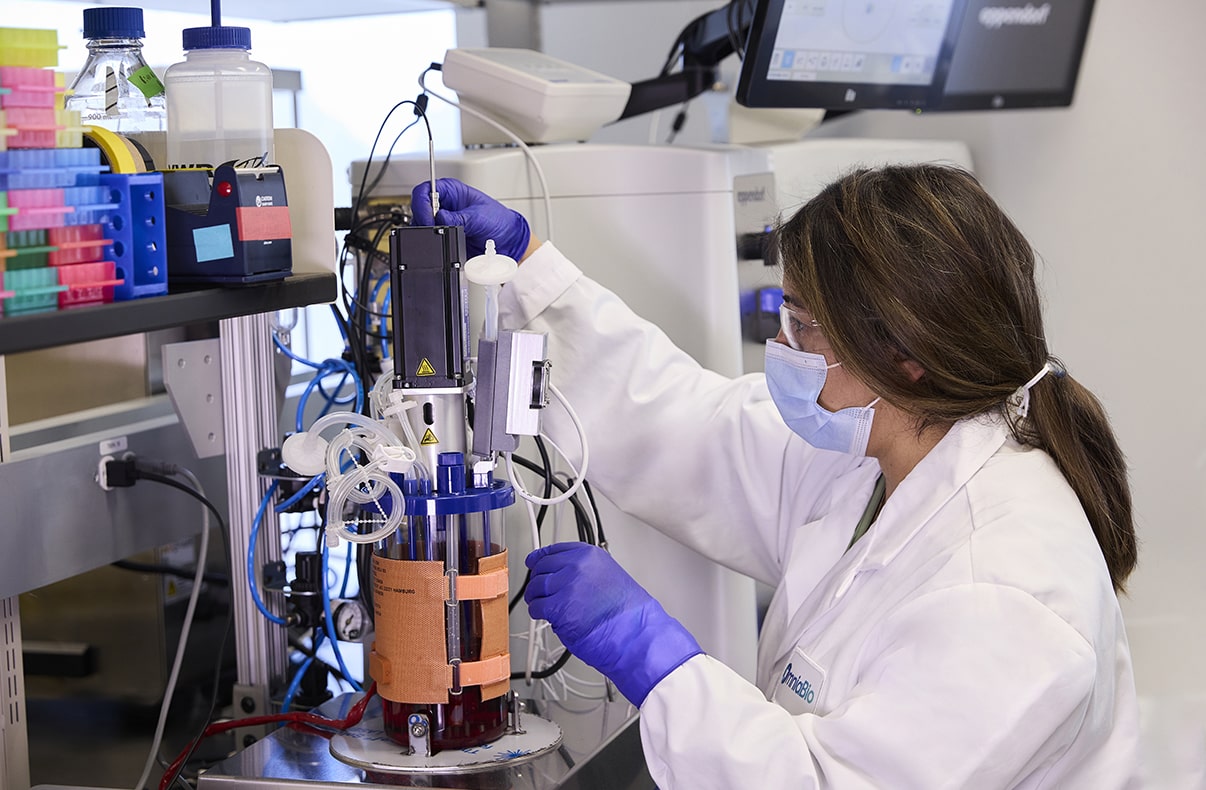

At OmniaBio, we constantly evaluate how novel technologies can be rapidly integrated into process workflows to streamline your cell therapy program.

Our technical experts develop and optimize manufacturing platforms integrating closed unit systems, AI models, and robotics so we can:

- Establish safe, scalable processes

- Achieve greater analytical control

- Ensure product quality and consistency

- Shorten processing times

- Lower cell therapy manufacturing process development costs

FEATURED TECHNICAL APPLICATION POSTERS

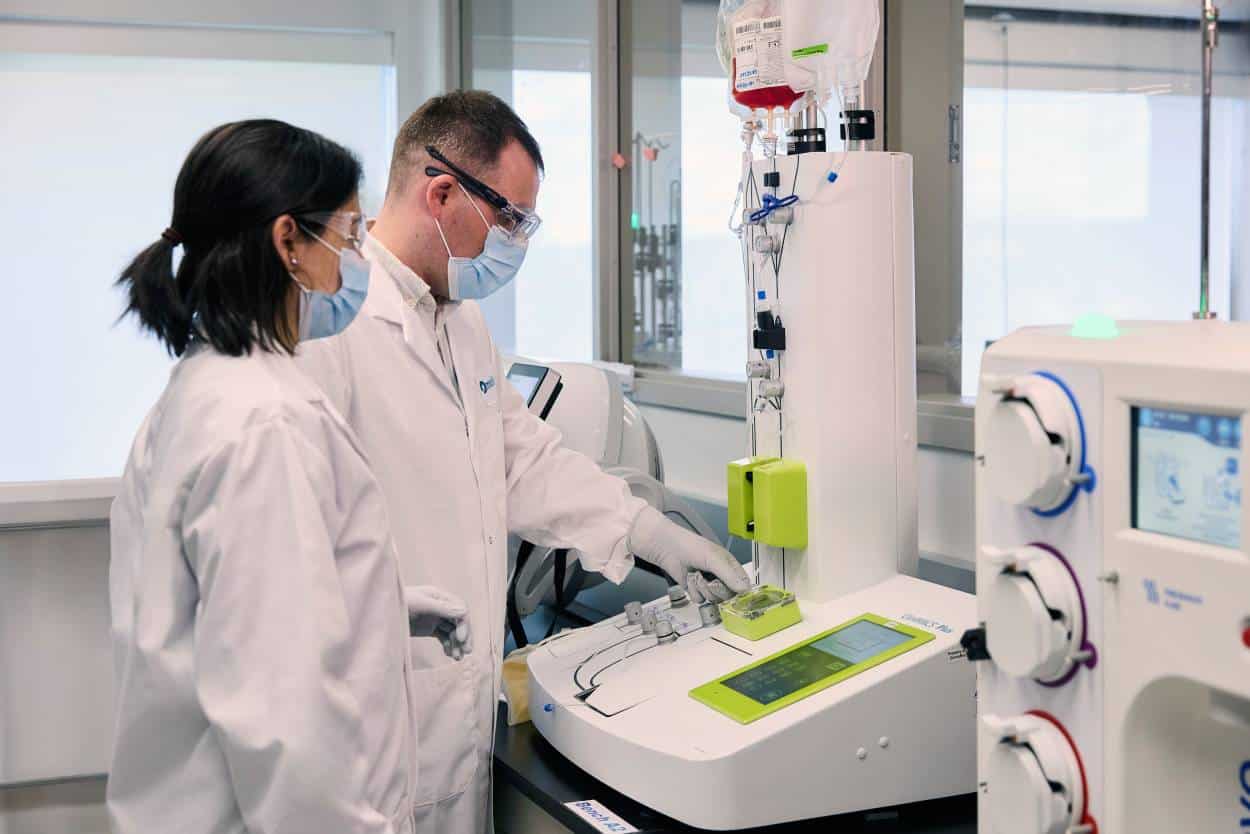

Flexible and Cost-Effective Process Development

CD19 CAR-T Cells Manufacturing

Discover how OmniaBio used CliniMACS® Plus (Miltenyi Biotec), G-Rex® (Wilson Wolf Manufacturing), and Cocoon® Platform (Lonza) as a starting point to develop efficient and economical processes for the manufacturing of CD19 CAR-T cells.

Robust Analytical Development for Process Success

Robust analytical development is crucial for ensuring process consistency, scalability, and regulatory compliance.

OmniaBio offers comprehensive analytical capabilities to support seamless process development and streamline transfer to GMP manufacturing and to the clinic.

Collaboration-First Approach: Your Goals, Our Focus

At OmniaBio, we are committed to working with our clients to fully understand their program specifics, timelines, and constraints so that we can ensure timely therapeutic delivery.

That is why our integrated development and MSAT teams not only create robust, scalable, customized process workflows at reduced costs but also help you select the right manufacturing platform upfront to mitigate delays and accelerate your cell therapy program.

Dedicated Cell Therapy Process Development and Tech Transfer Labs

OmniaBio intelligent factories span 19,500 ft2 dedicated to process development, analytical development, and technology transfer to streamline operations and expedite market readiness.

Our industry-leading process development facilities in Hamilton and Toronto, Canada, allow our experts to perform:

- Process closure, automation

- Cost analysis, risk reduction

- Workflow simplification

- Media development

- Culture intensification

FEATURED BLOG

The Vital Role of Process Closure and Automation in CAR-T Manufacturing

CD19 CAR-T Cells Manufacturing

Discover how customized solutions for system closure and process automation address critical technical bottlenecks, streamline manufacturing processes, and enhance patient access to life-saving therapies.

Let’s Talk About How We Can Help

Expedite your product from development to manufacturing with our industry-leading capabilities and tailored solutions.

Frequently Asked Questions

What are the key challenges in developing a scalable manufacturing process for cell therapy?

Developing a scalable process for cell therapy presents several challenges, including:

- Maintaining cell quality, potency, and viability across different scales of production.

- Ensuring reproducibility and consistency when transitioning from research to GMP manufacturing

- Managing raw material variability: Addressing inconsistencies in donor-derived cells and reagents by implementing robust qualification strategies, supply chain controls, and analytical methods

- Addressing regulatory requirements, such as Good Manufacturing Practice (GMP) compliance.

- Developing cost-effective automation solutions to reduce labor-intensive steps.

How do you optimize and standardize process parameters for consistency in cell therapy manufacturing?

Process optimization involves fine-tuning parameters to ensure reproducibility and scalability. Key activities include:

- Design of Experiments (DoE): Using statistical methods to systematically test and optimize process conditions.

- In-Process Controls (IPCs): Implementing real-time monitoring of key variables (e.g., pH, dissolved oxygen, metabolite levels).

- Unit Operation Platform Selection: Comparing different bioreactors and processing equipment to identify the correct system that maintains Critical Quality Attributes (CQAs) such as cell viability, potency, purity, and identity throughout the process.

- Media and Reagent Standardization: Establishing serum-free or xeno-free media for consistency.

- Process Analytical Technology (PAT): Integrating real-time sensors for data-driven process control.

What role does automation play in cell therapy process development?

Automation enables our team to:

- Improve reproducibility by reducing manual interventions.

- Enhance efficiency by enabling high-throughput processing of cell cultures.

- Reduce contamination risks through closed-system bioreactors and automated filling systems.

- Lower production costs by minimizing the need for highly skilled labor.

- Facilitate scalability, ensuring a smooth transition from preclinical to commercial manufacturing.