On October 17, 2024, OmniaBio welcomed over 200 guests to our Hamilton facility commemorating the opening of our purpose-built, commercial cell and gene therapy manufacturing and AI centre of excellence.

Loading...

By addressing challenges related to cost, production efficiency, and patient safety, allogeneic CAR-T cell therapies have the potential to make these therapies more accessible and consistent.

iPSCs are created by reprogramming differentiated somatic cells, which allows them to exhibit properties similar to embryonic stem cells. From a scale-up and manufacturing perspective, groups need the right support to achieve their goals in a time-efficient and cost-effective manner.

This blog will explore how developing customized solutions for system closure and process automation solves key technical bottlenecks, advances the manufacturing of, and ultimately patient access to, these life-saving medicines.

Selecting a CDMO partner that best fits your needs and is “just right” is critical. Discover the key factors to consider that can impact the success of your program(s).

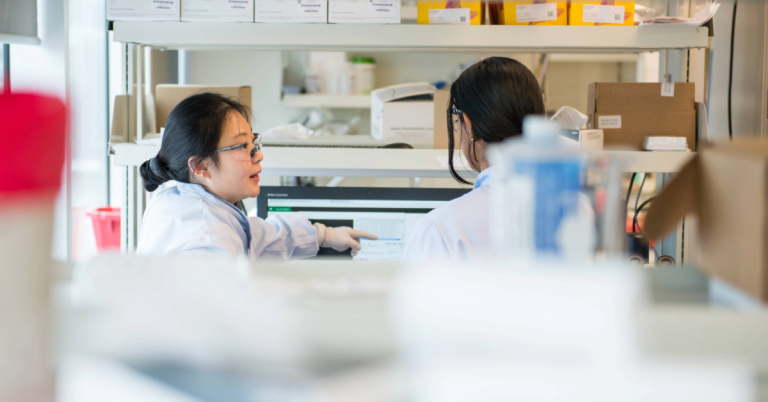

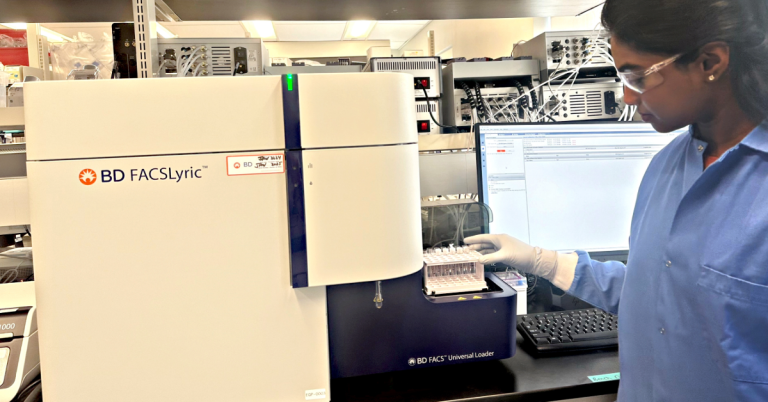

In this blog post, we highlight key considerations for analytical and quality control (QC) testing of cell and gene therapy (CGT) products.

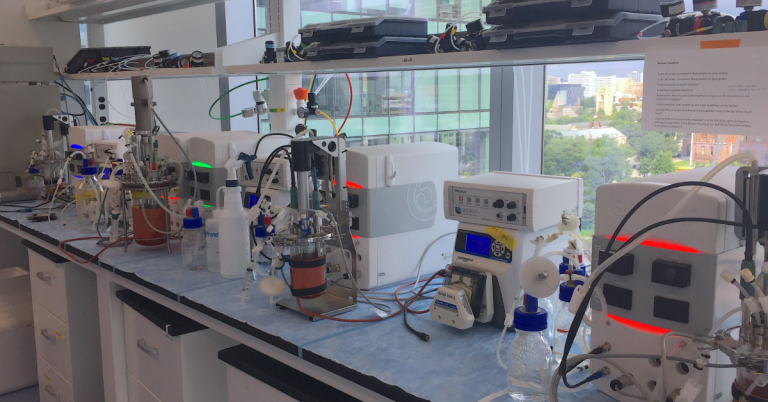

OmniaBio is working on overcoming the challenges of scaling up LVV production to reduce production costs and facilitate CGT's commercial production.

LVVs are essential in the manufacture of cellular immunotherapies (e.g., CAR-Ts). This blog post focuses on improving 3 broad areas of manufacturing LVVs.

Managing the manufacturing process for cell and gene therapy (CGT) products can be a significant challenge for contract development and manufacturing organizations (CDMOs) and their clients. Time is of the essence, as delays can affect capacity, resource planning and the path to product commercialization.

Regenerative medicine is bringing about an entirely novel therapeutic approach to treating human diseases, many of which currently lack efficacious therapies.