Autologous Cell Therapy Manufacturing

As the field of CAR-T cell therapy expands from hematological oncology indications to solid tumors and autoimmune diseases, your need for higher capacity, improved efficiency, and reduced costs has never been greater. At OmniaBio, we are revolutionizing autologous CAR-T cell therapy manufacturing.

Redefining CAR-T Cell Therapy Manufacturing

Technical Leadership

T Cell Platform Expertise

AI-Enabled Automation

Advancing CAR-T Affordability and Accessibility for Patients

Autologous cell therapies are currently costly due to labor-intensive processes, patient-specific batch production, and outsourced quality testing. Small batch sizes and stringent quality control requirements drive up the COGs, creating accessibility barriers for patients in need.

At OmniaBio, we are redefining CAR-T cell manufacturing to make transformative therapies more affordable and accessible. Through our focus on advanced automation, AI enablement, and on-site quality control across four critical areas, we can optimize your production efficiency and streamline batch release to reduce COGs and improve patient accessibility.| Advanced Donor Cell Screening | Leveraging machine learning, our system can help predict donor T-cell manufacturability and clinical efficacy, enabling higher chances of therapeutic success. |

| Automated Quality Control | By automating quality control processes, we reduce human involvement by 80% and achieve rapid release in just 3 days, streamlining time to patients without compromising safety. |

| Optimized Bioprocessing Footprint | With robotic “hotelling” of cell processing equipment established, our vertical and horizontal setups enhance throughput, increasing output per square meter by 300% for maximized space and scale operations. |

| Intelligent Vein-to-Vein Logistics | From donor raw materials to final drug products, AI-driven routing, tracking, and rerouting systems ensure seamless delivery, reducing logistical bottlenecks and improving overall reliability. |

Advanced Donor Cell Screening

Leveraging machine learning, our system can help predict donor T-cell manufacturability and clinical efficacy, enabling higher chances of therapeutic success.

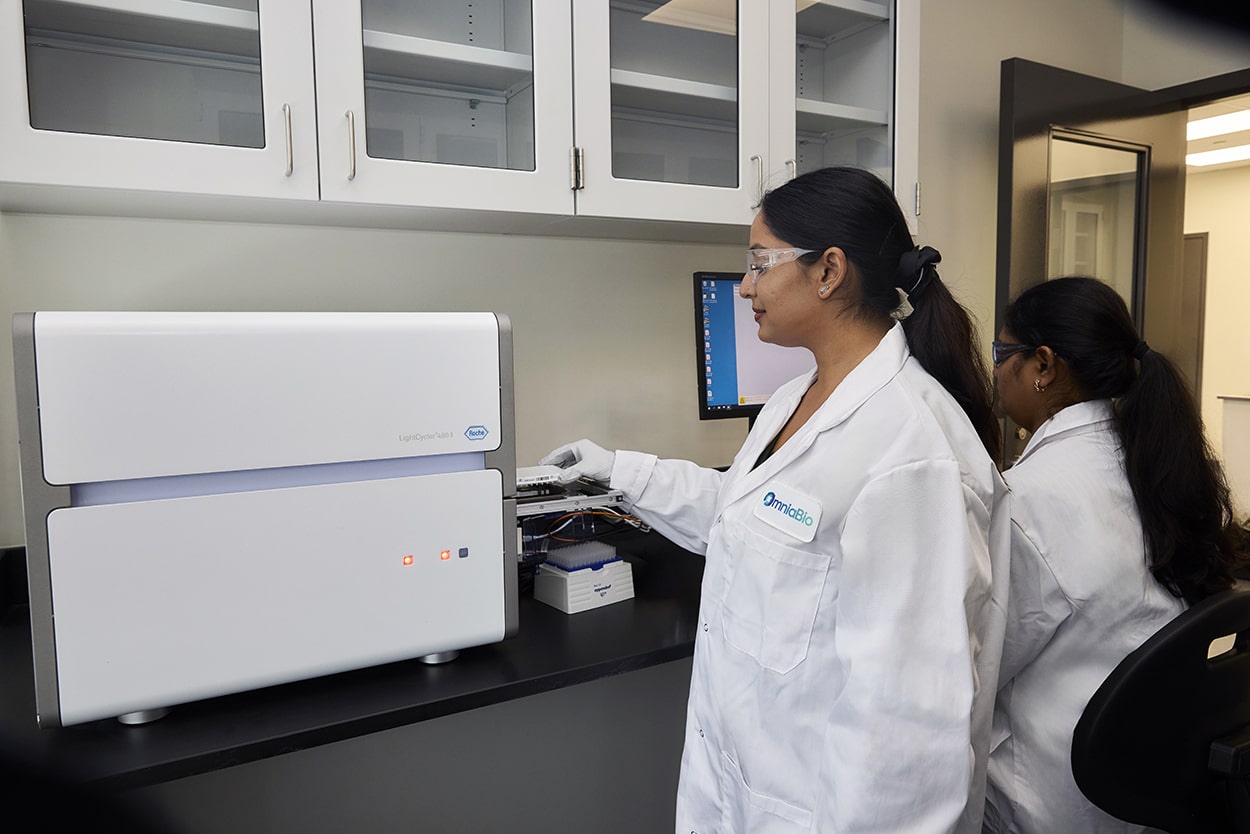

Automated Quality Control

Optimized Bioprocessing Footprint

Intelligent Vein-to-Vein Logistics

Technology-Forward Process Development

With over a decade of immune cell therapy experience, our technical experts develop and optimize manufacturing platforms integrating closed unit systems, AI models, and robotics to establish safe, scalable processes for you.

From T-cell isolation to GMP manufacturing, our integrated development and MSAT teams not only create a robust and scalable workflow at reduced costs but also help you select the right manufacturing platform upfront to streamline your CAR-T program journey.

FEATURED TECHNICAL APPLICATION POSTER

Flexible and Cost-Effective Process Development

CD19- Cells Manufacturing

Comprehensive Analytical Development & Quality Control

Our in-house analytical capabilities, including ELISA, flow cytometry, and qPCR/ddPCR-based assays for phenotyping, potency, purity, and identity testing, are essential to delivering consistent and reproducible immune cell therapy.

Through customized solutions and support based on your reagents, starting materials, in-process intermediates, and product-specific requirements, our team establishes robust analytical methods for a smooth transition to QC for use in GMP manufacturing.

FEATURED RESOURCE

Precise and Reliable Analytical Development

For Lentiviral Gene-Modified CAR-T Products Characterization

Read more about how OmniaBio optimized infectious titre (IT) and vector copy number assays using ddPCR and flow-based IT analytical methods. Discover how this customizable panel of analytics can support seamless transfer to GMP manufacturing and to the clinic.

Intelligent Autologous CAR-T Infrastructure

Equipped with 9,500 ft² of process and analytical development and technology transfer laboratory space, 16 cleanrooms, and over 31,200 ft² dedicated to cell therapy production, our facility in Hamilton, Canada, is purpose-built for scalable autologous CAR-T manufacturing, enhanced batch quality, and lower COGs for improved patient access.

Led by industry veteran Tony Rotunno, who oversaw 30,000+ autologous doses at a 98% success rate, our Intelligent Factory is designed to integrate robotics and AI for scalable throughput and seamless transition from clinical to commercial manufacturing.

Phase-Appropriate Capabilities

OmniaBio’s state-of-the-art GMP facility in Hamilton, Ontario, is designed to scale with clients across all stages of clinical and commercial production:

- Phase I: Low batch production to meet your early-stage clinical needs.

- Phase II/III: Capable of delivering up to 1,200 doses annually.

- Commercial Scale: Automated manufacturing scaling up to 5,000 doses annually by Q2 2026.

- Beyond 5,000 Doses: If you have larger demands, our facility includes infrastructure to expand capacity to 30,000 doses per annum, ensuring we can meet the needs of even the most ambitious therapeutic pipelines without any technical transfer.

Enhanced Safety and Quality: Why Automation Matters

The typical cell manufacturing process involves patient T cell isolation, cell engineering with viral and non-viral vectors, expansion to clinical quantities, and preparation for reinfusion, all under stringent GMP conditions to ensure the patient’s safety. But at OmniaBio, we recognize that GMP manufacturing alone isn’t enough. That is why we are bringing AI models, automation, and closed process units into our autologous cell therapy manufacturing platforms.

Our development team integrates automated and closed system processes into our workflows to minimize manual interventions and maintain a sterile environment at all times. Moreover, we built an intelligent autologous CAR-T manufacturing facility with robotics capabilities to mitigate human errors, so you can safeguard CGT products’ integrity and expedite high-quality, transformative treatments to patients.In-House Quality Control

Our 6,500ft2 dedicated QC lab enables in-house testing for direct quality control oversight, ensuring timely in-process and release testing results, especially for rate-limiting safety tests, and the scheduling flexibility needed to adhere to your program requirements and timelines.

By offering internal QC testing, we can help you eliminate delays tied to third-party testing, reduce costs, and accelerate the production and delivery of your autologous cell therapy products.Fill-Finish, Cryopreservation, and Storage Capabilities

Using fill-finish systems like Cytiva Sepax C-Pro Cell Processing System and Aseptic Technologies Crystal M1™ Filling Station, we support vial and cryobag formats in Grade A and B environments. Our fill-finish and storage options ensure the safety, efficacy, and accessibility of your autologous cell therapy products.

Our processes minimize contamination risks and ensure product integrity while offering scalable solutions from 0.1 mL to 220 mL, tailored to your needs. Our team performs final product inspection and reliably prepares your product for onsite cold storage or distribution.

Secure Supply Chain

Same Day Services to Anywhere in North America*

To DTW

To YYZ

To BUF

To YHM

Outbound: Under 18 hours

Same day services to anywhere in North America*

Outbound: under 18 hours

Let’s Talk About How We Can Help

We redefine autologous cell therapy manufacturing by offering solutions that shorten vein-to-vein timelines, enhance batch quality, and lower COGs for enhanced CAR-T cell therapy accessibility.